By Walek

High Feed end mill configuration

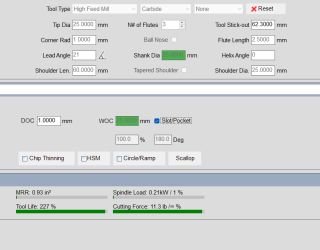

Hi! I encounter a wired bug. When I create High Feed Mill: Tip Dia: 25,000 mm Flutes: 3 Stick Out: 62,3 Corner Radius: 1mm Ball Nose: False F lute length 2,5mm Lead Angel: 21 Shank Dia 25mmm Helix Angel: 0 Shoulder Len 60mm Tappered: False Shoulder Dia 25mm Results for Slotting WOC is: DOC: 1,5mm WOC 19,7889 DOC: 1mm WOC: 25 mmm DOC: 0,9 WOC 24,9 DOC: 0,5 WOC 24,7321 I think with 0,1 DOC it should be between 14-16mm WOC. Maybe I put something wrong? Regards, Jakub Wałkowski

Eldar Gerfanov (Admin)

Hi, 2.5mm flute length seems very high for a HFM. For Feed mills the flute length is the maximum cutting depth. Also what material are you calculating it for? You are not going to see exactly the same values as suggested by your manufacturer because there is a lot of variance between different tools. From the little that I can see on the screenshot it looks OK. Best regards.