By apowellgt

Feed/Speed Calculation with Custom Power Curve

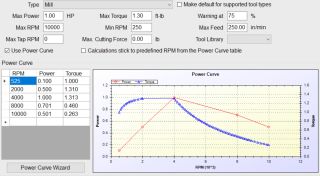

I've created a custom power curve for my machine in HSMAdvisor. I realize this power curve may not be correct or realistic for my mill (a Tormach 770MX), but when generating a cut formula I noticed something curious. If I let HSMAdvisor select the RPM and Feed Rate, it returns 10000 RPM (machine max) and 66 IPM (see screenshot) for a 1.48ci/min MRR. However, if I manually set the RPM on the same cut to 7500 RPM, the software calculates 97 IPM for a 2.18ci/min MRR -- presumably it's able to do this because there is more spindle power available (in my imaginary custom curve) at 7500 RPM than 10000 RPM: 0.38 HP vs 0.55 HP. Should HSMAdvisor select the RPM and Feed that produces the highest MRR along the power curve, or am I missing some other factor?

Eldar Gerfanov (Admin)

Updated by: Eldar Gerfanov (Admin)January 4, 2026, 10:20 pm

Hi, Thank you for your question. Several years ago, HSMAdvisor would try to reduce RPM to maximize the Material Removal Rate. But that led to conflicts with other limits, so I decided to remove it. (One of which is it has to find a local maximum on the power curve, change RPM and then recalculate everything, possibly triggering some other alarm, thus faulting the whole calculation.) The way it works now. It gives you the suggested Cutting Speed and then limits the Feed Rate to make it fall within the power curve. This is only noticeable when you don't let HSMAdvisor calculate at least one engagement (DOC or WOC) value. I hope this answer was helpful. Best regards.

apowellgt

Thanks for getting back to me. (And for making the software. I'm a happy customer, and it's teaching me a ton.) It's helpful to know this is expected behavior. I'll try letting HSMAdvisor select WOC and see how that changes things.