By Gmack

Avid CNC Benchtop Pro vs Mild Steel

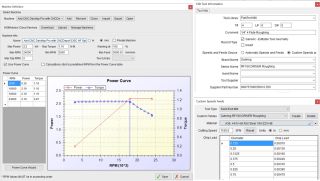

Regarding your recent blog post "Avid CNC Benchtop Pro vs Mild Steel - can we cut steel on a desktop gantry router?" https://zero-divide.net/?&article_id=5258, couldn't Breaking Taps have achieved results comparable to those you posted for a HAAS machine by using a different endmill as shown below? Is there a way to force HSMAdvisor to use endmill manufacturer speeds and feeds (i.e. SFM and IPT in this case) for RPMs and Feed Rates?

Eldar Gerfanov (Admin)

Hmm, I am not 100% sure, but I think this would burn up the End Mill pretty fast. Over 1000 SFM at 25% engagement is very fast. If you want to use the manufacturer S&F You should use the values manufacturers give for general shoulder roughing. IE at 60% radial engagement. Also why is your stick out 2"? Try to use tools as stubby as possible. In short I do not think this would work out. SFM is way too high

Gmack

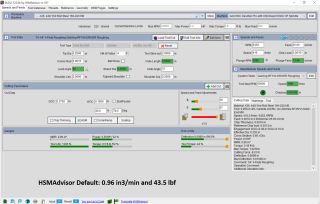

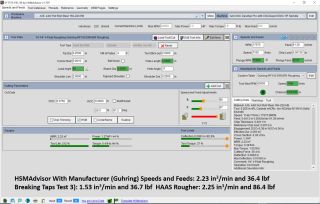

I backed off some on the manufacturer's (https://www.guhring.com/ProductsServices/SizeDetails?EDP=9067590063520&fromResults=True) 40% WOC "HIGH-VOLUME ROUGHING" recommendation to keep cutting forces acceptable for the machine/configuration. I used 2" stick-out (the shank length) when I stored the endmill and forgot to change it to a more reasonable 0.6". But, I suspect that the overall spindle stick-out will dominate overall machine defection anyway.

Eldar Gerfanov (Admin)

This is something I need to see to believe. In my experience 1000 SFM slotting any steel will result in burned up End Mill.

Gmack

Eldar Gerfanov (Admin)

I didn't realize that was the NaCo coating. Yes it can slot free-machining steels at SFM close to 1000. I am away from my computer at the moment and can't run all the numbers...

Gmack

Guhring claims a “nano-Si” coating. Is that the same as NaCo? Is NaCo compatible with aluminum? Where did your endmill screenshot come from? Unless I screwed up, I’ve already “run [and previously posted] the numbers” for roughing with Guhring’s speeds and feeds. I forced HSMAdvisor’s “RPM”, “Feed (in/min)”, “Speed (f/min”), and “Chip Load (in)” to match Guhring’s cutting speed (SFM) and reference chipload (IPT). I used their depth of cut (ap - “DOC”) but reduced the width of cut (ae - “WOC”) to achieve an apparently acceptable cutting force (~36 lbf) for the machine and its configuration. Should Breaking Taps use climb milling (as shown in Guhring’s videos) to minimize rubbing and minimize overall spindle/endmill stick-out to possibly enable higher acceptable cutting force? Maybe add the high performance Guhring endmills to HSMAdvisor’s tool data base along with the ability to easily force HSMAdvisor to use them? If users where allowed to set either DOC or WOC, HSMAdvisor could adjust the free (unset) parameter to whatever is necessary to keep the machine power, force, and endmill deflection at acceptable levels.

Eldar Gerfanov (Admin)

Hey Gmack, The good news is easily-accessible Manufacturer-specific tool definitions are in the works. Regards.

Gmack

Awesome - Thanks! Reducing cutting forces by increasing spindle speeds and cutter diameters can apparently significantly increase the capabilities of gantry CNC routers. But, isn't there a minimum force requirement (dependent on material shear strength and cutter engagement area?) to actually cut the material? What are typical cutting edge radii of a typical tungsten carbide endmills?

Eldar Gerfanov (Admin)

Gmack

Isn’t the shear force requirement, which depends on the cutting cross-section area, different from the cutting force which HSMAdvisor calculates from cutting power/MRR? Are cutting edge radii proportional to cutter diameters like chiploads often are?

Eldar Gerfanov (Admin)

Updated by: Eldar Gerfanov (Admin)January 7, 2026, 4:01 pm

Gmack

Either I lost the ability to post an image here or forgot how to. Could you please remind me?

Eldar Gerfanov (Admin)

Updated by: Eldar Gerfanov (Admin)January 7, 2026, 4:01 pm

Yeah i accidentally disabled the upload feature. Should be fine now: Test Upload.

Gmack

The "X" box over the "Browse..." box seems to block me from browsing for images to upload.

Eldar Gerfanov (Admin)

Gmack

Seems ok now - thanks! Here's what I was asking about.

Eldar Gerfanov (Admin)

To be honest, I do not think your formula is correct... According to it if cutting edge radius was 0, the cutting force would also be 0? Seems wrong.

Gmack

If the cutting edge radius is 0, the <span style="display: inline !important; float: none; background-color: #ffffff; color: #000000; font-family: Verdana,Arial,Helvetica,sans-serif; font-size: 16px; font-style: normal; font-variant: normal; font-weight: 400; letter-spacing: normal; orphans: 2; text-align: left; text-decoration: none; text-indent: 0px; text-transform: none; -webkit-text-stroke-width: 0px; white-space: normal; word-spacing: 0px;">shearing </span>force would be zero. But the force required to remove the material wouldn't be. Think of it as shoveling snow with one of curved plow type shovels. Penitrating the surface typically takes far less force than the actual shoveling process.

Gmack

Trying to post the last comment again - by directly going to the forum rather than through HSMAdvisor. If the cutting edge radius is 0, the surface shear force would be also be 0 (no power is required). But power (hence cutting force) is required to remove the material after it's surface is sheared.

Gmack