By ecnels

Updated by: Eldar Gerfanov (Admin) May 15, 2016, 3:44 pm

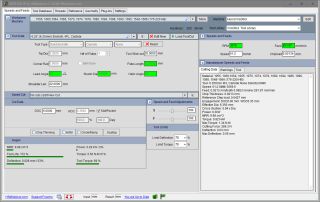

Tool Breakage on 6.35mm Carb Mill

Just started using HSMAdvisor and setup a 1/4", 4FL endmill for 1018 steel; however, when I cut with the settings showing in the Advisor it breaks the mill after moving to depth and attempting to contour a slot. Since this is my first shot at using HSMAdvisor, I figure I'm doing something wrong in the settings. A screen print of the settings is enclosed. Ideas? Thanks!

Eldar Gerfanov (Admin)

Updated by: Eldar Gerfanov (Admin)May 14, 2016, 6:16 am

Hi, What happens in your screenshot is you are using too much on a depth of cut. You can see that your deflection and torque are very large. Though they seem to be below critical values, you just don't have enough chip clearance on your cutter to pull it off. Simply click either DOC or WOC label to have it suggest better number. There is a Performance slider on Speed and Feed Adjustments panel. For such long endmills it helps to have that one all the way to the left. Also make sure you specify correct work material and tool geometry data. I see you did not modify Flute lenght. Are you sure it is what it shows on the screen? Flute length is very important for deflection and proper DOC suggestion. Please let me know if this helps. Otherwise we would have to dig deeper. Regards.