By ndlsjk

Lathe - Boring Speeds and Feeds

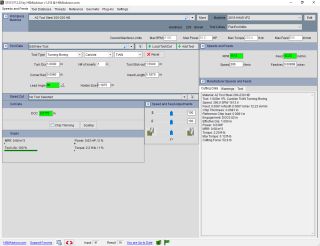

Hello all, First off just want to say major thanks to Mr. Gerfanov for the wonderful tool he has created in HSMAdvisor. I have a a few newer (2012 and up) Haas machines and the speeds/feeds and WOC/DOC that have been recommended on the mills have been dead on in aluminum, A2, D2, 1018 and A36 HRS and increased my productivity by multiples. The question I have is regarding the lathe feeds and speeds. I have a small Haas CNC Lathe (TL1) and am having difficulty with the recommended feeds and speeds, especially regarding boring operations. I typically run small (3/16", 1/4") boring bars that are carbide with a brazed on tip with coated carbide inserts. I have attached a screenshot of the recommended feed and speed for a 1/4" bar that I tried to run and had chatter and visible deflection from the first pass in A2 tool steel. I am inexperienced on the lathe and can not figure out how I am supposed to come even close to the numbers the calculator presents. I have found success at approximately 75 SFM, 0.00808 FPR, and 0.005 DOC. This is 1/3 the DOC and less than 1/4 the surface speed the calc has recommended. Is this bar just too long and not being compensated for in the calculator properly? I have tried with a 0.2500 bar and 0.3750 bar and all of them chatter so bad I am lucky to not have broken one already (and these are $100+ bars, good quality tools). Is there a secret to the lathe side of HSMA I have not figured out? Sorry about the book, I just looked for a long time and in the help and forums for someone with the same problem and couldn't find it, so I decided to create a detailed post explaining what I need. Thanks in advance, Jake Jones

Eldar Gerfanov (Admin)

Hello Jake, Just call me "Eldar". "Mr. Gerfanov" sounds too official :) Thank you for all the good feedback regarding milling speeds, feeds, DOC, etc. It means a lot to me to hear first-hand that my software is helping others safe time, money and tooling, all while improving productivity! And especially thank you for all the BAD feedback regarding turning speeds and feeds. Unlike some other businesses, I am not trying to control or vet messages that are posted on my forums. All the feedback is up here for everybody to learn from. Just as you guessed there is a certain lack of functionality in Turning module. I used 1" holder size to set all feedrates for turning. And when a smaller size holder is used, feedrate does not get compensated for that (Currently only DOC gets reduced). It is normally OK for holders and boring bars down to 3/8" in size, but for anything smaller, like in your case, it ends up too heavy on the feedrate. I am currently forking on improvement to the Turning module and a fix will be available in the very next update. I will let you know when I release it. Do you have any other concerns with Turning, other than the ones we are currently discussing? If you do, please let me know, so I can improve our software! Regards. :ernaehrung004:

ndlsjk

Eldar, Thanks for the quick reply and confirming my suspicions. I will be eagerly anticipating the next release with the updated lathe calculations. As far as any other issues, I do not believe there are any. Everything seems to be working the way I would expect it to. -Jake

Eldar Gerfanov (Admin)

Jake, I believe the changes i made to the turning module in the latest update will fix the reported issue. Please try it and let me know if something needs a second look. Regards!

ndlsjk

Eldar, We finally got around to testing the new speeds and feeds (been SUPER busy around my shop the past couple weeks) for the lathe (outside turning in A2 tool steel) and we are definitely much closer now. Our lathe is not the most stout (2014 Haas TL-1) so we need to be a little cautious on our depth of cut but I think the speeds and feeds recommended are pretty awesome. Like I said we have only had maybe an hour of playing with it and then had to get back to pumping parts out from the mills but I will stay in touch and especially let you know regarding the tiny boring bars when we start using them again. I punched a few quick numbers in and it seems like we were actually fairly close with our "SWAG" numbers to what the calculator is providing. Thanks for the quick update and working on this issue for me, Jake PS - We only were able to test with a pretty worn insert because the tool lady that drives a truck around and delivers our inserts was out of stock last week. I think she said she will be back on Friday with a fresh box of inserts and we can really go crazy then and hopefully step up to the DOC recommended in the calculator.

Eldar Gerfanov (Admin)

Hello Jake, Well... If it is "fairly" close, then i am happy. Keep in mind that "SWAG" numbers on your machine may be quite "meh" on some others and vise-versa :) Thank you for finding the time to leave the feedback. If you have any concerns or questions - let me know. :ernaehrung004: