By williamlynn

SPEED CALCULATION

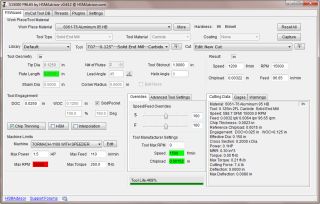

I am getting strange SPEED calculations with HMS Advisor DEMO. I want SPEED for 1/8 dia at 15000 RPM. HMSAdvisor gives funny SPEED calculations as shown in attached screenshot. When I do the same in FSWizard:online or FSWizard:Mobil I get the correct speed which is 491 ft/min. What is "Effective Dia" shown in cutting data. Bill Lynn

Eldar Gerfanov (Admin)

Updated by: Eldar Gerfanov (Admin)December 26, 2013, 11:02 am

Hello Bill, In your tool geometry you have defined a chamfer mill with a 1/8" tip, 45 degree lead angle and 1/2 shank diameter. Those tools are very strong because of increasing diameter they will give you high feedrate. Effective diameter is the diameter of the cutter that is engaged with the material. You have a tapered tool and the deeper you cut, the bigger will be the effective dia. And SPEED is calculated using effective dia. So in short, the calculation looks correct. But i think you have made a mistake defining you geometry. If in fact you are using a regular straight endmill, you will snap it because chipload is too high. Below is a sketch of your tool. By the way whenever you want to reset everything to default just click "reset all" button in the top right corner. Bye.

williamlynn

:hammer3: Thanks for the quick response; I did not understand the LEAD ANGLE field; I assume that a straight end mill has a 90 deg LEAD ANGLE. When I changed this field everything looks good. But now I need some guidance on using the Speed/Feed Overrides window. Anything you can add. Thanks again Bill

Eldar Gerfanov (Admin)

Sure. Speed/Feed overrides allow you to adjust cutting speed and chipload. Adjustment of speed allows you to control tool life and chatter. IE if you wish to get longer tool life you can use 75% cutting speed. This will give you twice longer tool life than 100%S would give. Feed override (F) is often used to control deflection. Any time you see deflection above 0.001" you should be concerned. In order to decrease cutter deflection and to prevent cutter breakage you should decrease your cutting depth and/or reduce the feed override. Also in the advanced tool settings there is a slider called "Tool Productivity" You can move that slider all the way to the left and it will go very conservstive on depth of cut and deflection. I strongly recommend you using that last option. Especially if you machine is not rigid, or you endmill is sticking out very far. Like that 1/8" endmill sticking out 1" - thats alot. Feel free to ask more! Bye.