By cunder

October 9, 2014, 6:57 am

Feed rate

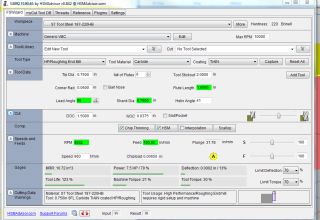

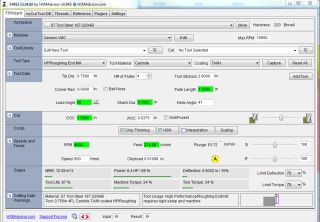

Using version .842 I selected S7 tool steal, generic VMC, HP rough mill, .06" corner radius, chip thin, HSM. I am getting a slower feed with a 6 flute than with a 4 flute. Am I missing something?

Eldar Gerfanov (Admin)

Updated by: Eldar Gerfanov (Admin)October 9, 2014, 8:03 pm

What happens is HSMAdvisor thinks that the 6 flute endmill should be run at lower radial engagement. Part of that is the fact that S7 is not that hard and HSMAdvisor actually increases the feedrate for the 4 foule tool, becuase it has more chip clearance and can take bigger bite without clogging up. Click on WOC label to reset the Width of Cut field to see what it suggests. I am sure at lower WOC, your feedrate will be much higher. And if you still think current WOC is manageable for the cutter, increase the Performance slider. What it does, it lets HSMAdvisor know, the tool can handle more engagement. Let me know how it goes. I can always change things to better reflect the real world conditions UPDATE: There was indeed a mistake made by me. Something weird happened when jumping from 5 flutes to 6.... Everything is fixed now, so please download the latest update.