Due to the current situation with lack of N95 masks in the stores I resorted to 3D print a pair for me and my wife.

I also made the designs freely available on thingiverse: https://www.thingiverse.com/thing:4264883

Here is the description of the project:

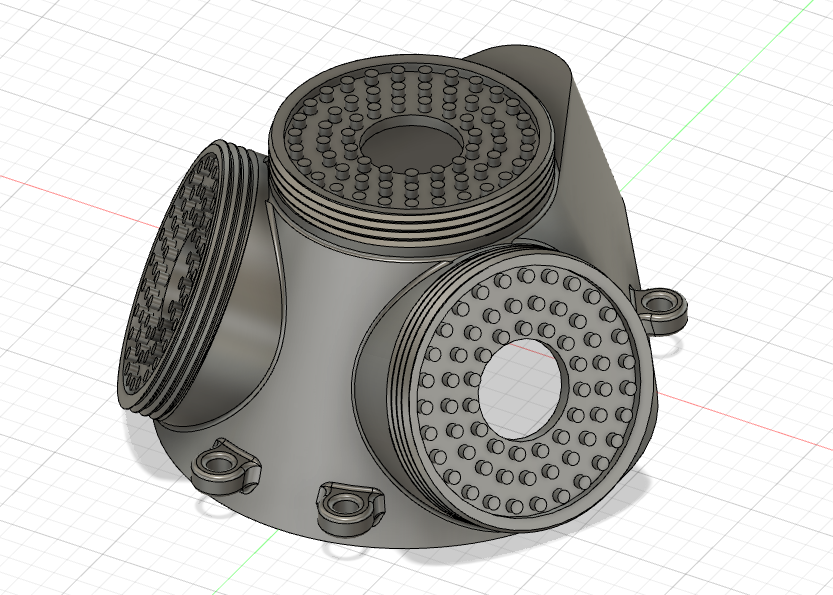

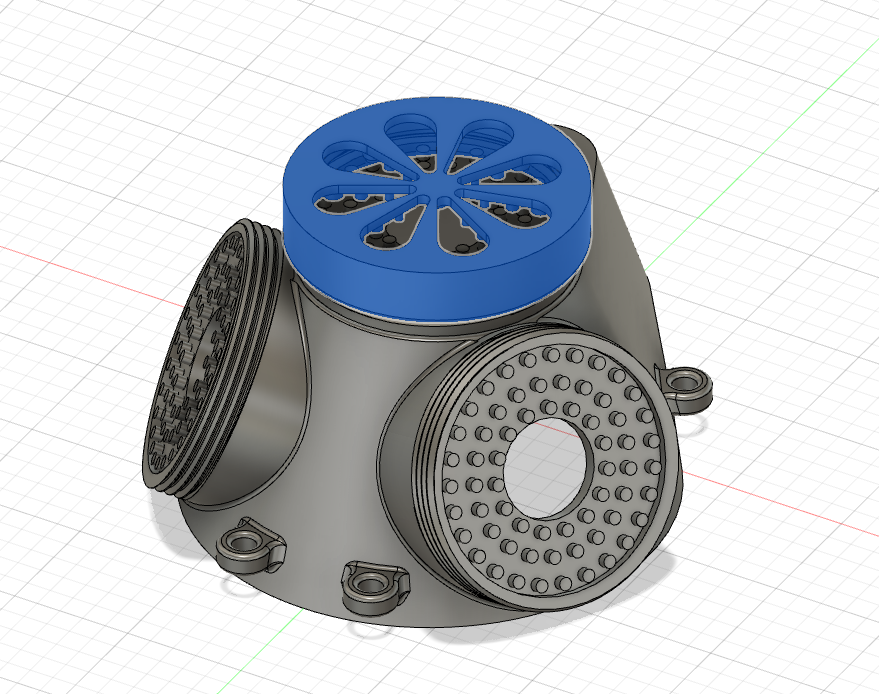

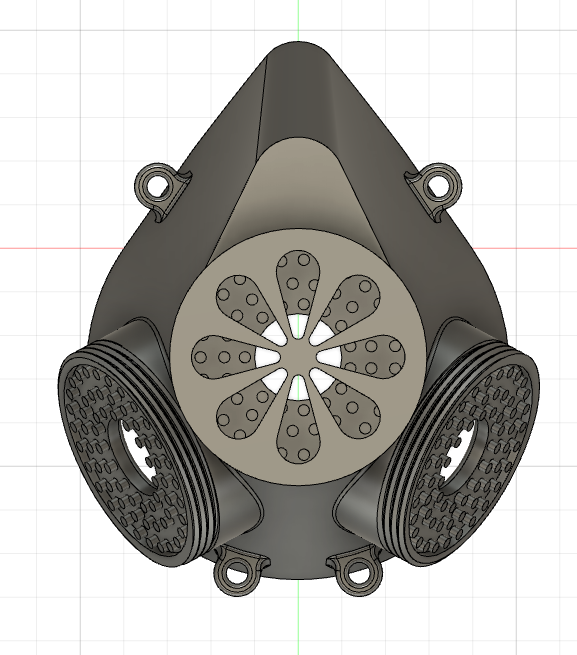

High airflow Respirator mask in 3 sizes: Large, Medium and Small.

Large works for a large male face. 125mm height*

Medium for a smaller male face. 115 mm

Small works for a female or a 10 y/o kid face. 105mm height.

*I measure face height from chin to the centre of the nose bridge.)

Designed to take 1 or 2 55mm cotton pads into each of 3 filter housings.

Install filter medium into the bottom of the cap and screw on to the mask body.

Make sure to print 3 caps for each mask as well. Caps are the same for all mask sizes.

Used white window insulation sticky cord on the inside to add cushion and improve insulation.

Had to also use a file and fine sanding paper to make sure the mating surfaces on the mask body are smooth and do not have any air gaps.

Disclaimer: I designed and printed this for me and my family. It has not been tested, and although I designed with safety in mind, I do not claim it can prevent any infections or viruses. Use at your own risk. PLEASE be careful when testing: different cotton pad brands have different density and 2 pads per filter may cause difficulty breathing! Please make sure to remove the filters and sanitize the mask and caps after each use.

The models are designed in Fusion 360.

Parts printed on Creality Ender 3S Printer with the following settings:

- Layer Thicknss: 0.2mm

- Infill: 20%

- Filament Material: PLA

- First Layer Speed: 35mm/s

- Wall Speed: 75mm/s

- Support: everywhere

- Support Speed 75mm/s

- Support Density: 1 line at 5%

1 mask plus 3 caps takes about 14 hours to print at: 75mm/s.

Please wash your hands and stay safe.

We will get through this!