HSM or High Speed Machining is becoming more and more popular each day.

Many of us have seen those youtube videos where endmlls remove large amounts of material at high speeds/feeds.

While definitions of HSM may vary between tool manufacturers and even individual shops, the physics behind it remain the same.

In this article i would like to explore flat endmills.

HSM is not about ramping up your speed/feed overrides to 200% and puling out your smartphone to record another youtube-worth video.

What is HSM?

HSM is a complex of programming, machining and tooling techniques aimed at radical increase of productivity.

Programming

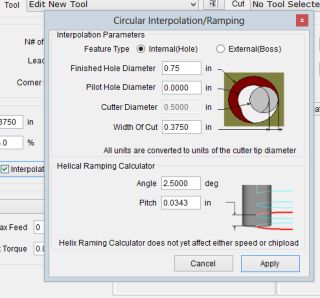

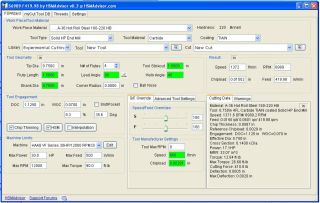

The cornerstone of HSM is low radial and high axial engagement of an endmill with the workpiece.

There are many CAD/CAM systems that allow you to create HSM tool-paths. Mastercam's Dynamic milling and SurfCAM's Truemill are some of them.

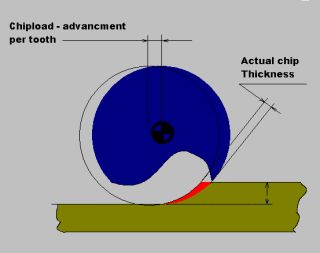

When radial cutter engagement with the material is smaller than the radius of the tool an interesting thing happens.

Chip load- the distance the tool advances per cutter revolution per tooth- does not equal the actual chip thickness anymore.

Chip thinning mainly happens at radial engagements below 30% of the diameter.

Radial Engagement vs chip thinning factor

| 100% |

1.0

|

|

| 50% |

1.0 |

| 30% |

1.091 |

| 25% |

1.212

|

| 20% |

1.641 |

| 15% |

2.1 |

| 10% |

4.375 |

| 5% |

6.882 |

In order to get compensated chipload you need to multiply recommended by manufacturer chipload by the chip thinning factor.

Usual Radial Engagement for HSM toolpaths however is between 5 and 15%.

Axial depth of cut varies depending on geometry, but Read More