At my day job I am starting to do more and more manual programming.

Which i do not realy like, but since am at it anyway i have decided to keep piling little articles about G-Code programming into this new category.

This way when i forget things again i will be able to quicly refresh my memory.

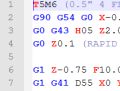

Program Start

O0001 (COMMENT OR PROGRAM NAME)

Starting safety blocks

(G20 IMPERIAL UNITS, G21-METRIC)

(G17 XY ARC PLANE, G18-XZ, G19-YZ)

(G40 CANCEL TOOL RADIUS COMPENSATION)

(G49 CANCEL TOOL LENGTH OFFSET)

(G80 CANCEL CANNED CyCLE)

(G90 ABSOLUTE POSITIONING MODE)

G20 G17 G40 G49 G80 G90

Tool Change Routine

(T14 - call 2.5" Face mill)

(M6 - Perform tool change)

(G0 - rapid feedrate)

(G55-G59 - Choose Work Offset)

(X, Y - Command a Position to move to)

(S - choose spindle speed)

(M03 - Turn spindle on Clockwise, M04 - Counter-clock wise)

T14 M6

G0 G54 G90 X{X} Y{Y} S{SPEED} M03;

Apply Tool length offset at retract height, Turn on Coolant

(G43 H14 Z2.0 - All codes must be in the same line Apply cutter length offset from record #14 to cuttent tool, move to 2.0 above work at the same time )

(M8 - Turn on Coolant)

G0 G43 H14 Z2.0 M8

Rapid tool to plunge height

G0 Z{Z_PLUNGE}

Plunge to cutting depth at plunge feedrate

G01 Z{Z_DEPTH} F{F_PLUNGE}

Make a straight cut in xy direction at cutting feedrate

G1 X{X_POS} Y{Y_POS} F{F_FEED}

Retract to plunge height at either rapid or retract feedrate

G1 Z{Z_PLUNGE}

Retract to rapid height, turn off colant

(M09 - Turn OFF coolant)

G0 Z{Z_RETRACT} M09

Retract to tool change height, turn off spindle

(G28 G91 Z0 - all coes must be in the same line, move Z axis to HOME POSITION through a reference point)

(G91 Z0 - Causes reference point to be the current location, thus sending axis straight up )

(M05 - Turn off spindle)

G0 G28 G91 Z0 M05

Perform Next tool change or end program

M30(end program)