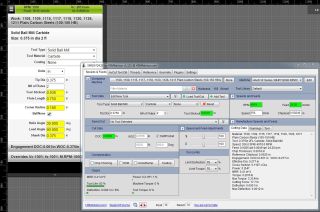

Lessson 3: CNC Canned Cycles, Drilling, Tapping, Reaming and Boring Cycles

Canned cycles are used every time we need to drill, ream or tap holes on our CNC machine

Standard Fanuc G-Code language supports more than a dozen canned cycles.

The most common cycles that will cover 99.9% of your g-Code CNC programming work are:

| G-Code | Name | Motion Style |

| G81 | Standard Drilling | Feed-In, Rapid-Out |

| G83 | Deep Hole Peck Drilling | Incremental Feed-In by Peck Distance, Rapid Out, Repeat |

| G84 | Right Hand Tapping | Feed-In,Reverse Spindle, Feed-Out |

| G85 | Reaming/Boring | Feed-In, Feed Out |

Subsequent holes

You can drill additional holes After your canned cycle has been initiated.

Any line with X Y position will be treated as another hole position.

Each position can have its own Retract value, feed rate and retract height modifier.

G80 - Canned Cycle Cancel Code

After all the holes of the canned cycle have been drilled, it is required to call G80 code in order to cancel the current cycle.