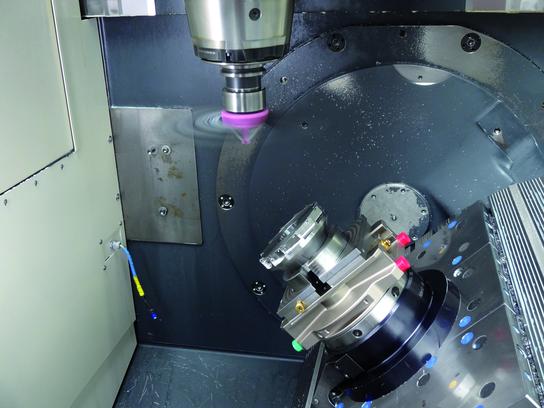

True 5 Axis Machining

Just saw this very impressive machining video on Practical Machinist forums.

A very nice example of using machine and the tools to their full potential.

Just saw this very impressive machining video on Practical Machinist forums.

A very nice example of using machine and the tools to their full potential.

The MC 2017 has been out for a few month now and because it has received quite mixed reviews from the machinist's community, i decided to release one more big update to our MCx9 hook before starting to fully work on adapting it for MC 2017.

This update v1.402 is a double update. The hook version has now caught up to the standalone AND we have some new features in standalone HSMAdvisor as well.

Here is a quick video showcasing most of the new features:

As usual Here you can download the latest updates: http://hsmadvisor.com/

Questions, troubles? Let us know via email or our support forums!

Regards.

This is 21st century and we all live in the age of the Internet.

While some software developers claim to use it for the benefit of the customers they in fact only care about license protection benefits it can provide.

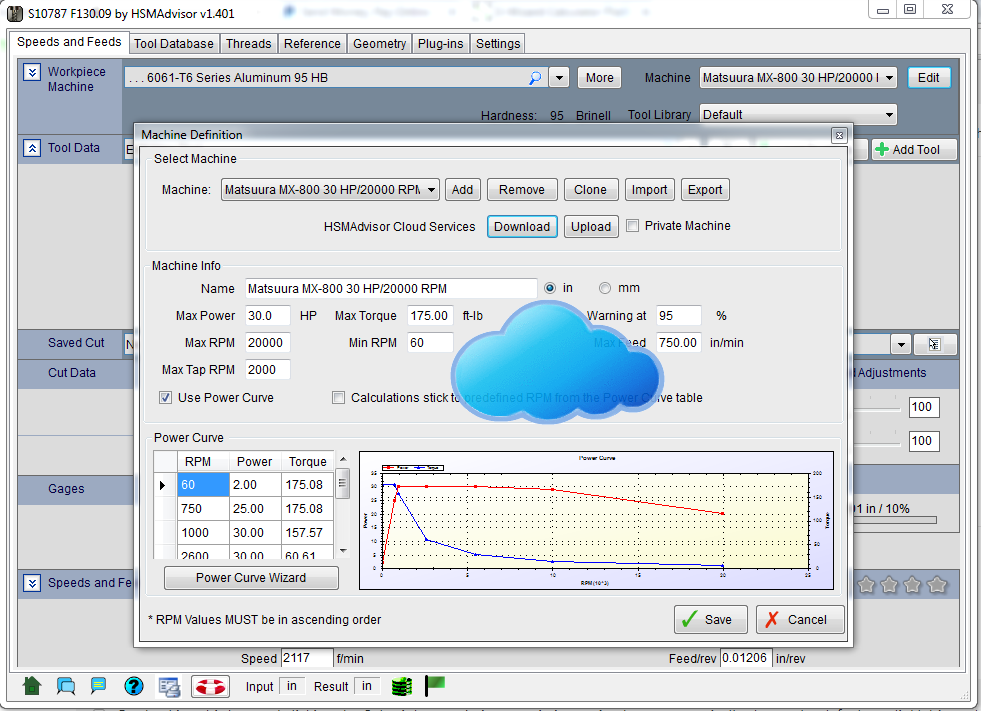

Here is how HSMAdvisor Speed and Feed Calculator uses the big WWW for the benefit of its users:

There is a lot more work planned and already in progress.

In the age when everyone is talking about how internet is turning the world around we are doing our small part in making it happen!

Thank you, everybody for your support and feedback!

As unhappy I am to learn that something may be wrong with the software I develop and love, negative feedback is essential in learning whether i am doing everything right.

So a couple of days ago I received an email from a somewhat disappointed user.

He (lets call him Peter) was complaining that HSMAdvisor calculator gave him "excessively high" speeds and feeds for his 3/4" 4 flute 3.0 LOC end mill in aluminum.

With the data Peter entered he was getting around 10000 RPM(SFPM 2117) and the feed of 270 inches per minute while usual practice in the shop was side-milling aluminum at that (2.8" axial) depth at only 325 SFM

After double-checking the numbers I replied that in fact his numbers seemed very slow and if for some reason he HAD to run that slow (heck, i machine most steels faster than 325 SFM) due to some conditions, perhaps, he was ought to change the conditions themselves.

This is what I am getting for Peter's end mill setup:

This means that from now on the access to Tool Database and Reference functions is completely free no matter whether you paid for our software or not!

This also means that Expired Floating licenses roll back to "Lite" mode where your machine power is limited by the number of years in your subscription.

A single 1 year subscription will buy you one year of unlimited use and then your machine power will be limited by whatever many years you have been subscribed for.

It will in fact work as a more expensive lifetime subscription!

Similarly a 3 year subscription will give you unlimited use for 3 years after which your power will be limited by 3 Horse Power.

In both cases You will also get all the updates and support that naturally comes with all paid options!

I believe this will be a great help for those running light underpowered machines like Tormach 770, Carbide 3d and such.

Comments?

Suggestions?

Let us know!

HSMAdvisor inheritantly supported calculating cutting parameters for T-Slotting (Woodruff) cutters before. All that needed to be done was to specify prope shank size and helix angle.

One of HSMAdvisor users asked me for help figuring speeds and feeds for machining stainless on his underpowered Tormach 700.

He volunteered to send me a model to work on, so I decided it was a good opportunity to make a learning video and share it with everybody.

I must say programming for such a low-power machine is a lot harder than for a full-blown production VMC where you are not worried about stalling your machine with anything under 1" in diameter:

Your thoughts and comments are always welcome.

We are actually listening to our users!

I have been working hard to improve not only HSMAdvisor lately, but FSWizard Mobile CNC Machinist App too!

The latest update improves productivity, speed, fixes a lot of small glitches.

And it also adds a completely new GD&T reference tab to both the FSWizard Free and PRO apps.

Update: FSWizard PRO and Free apps have just been approved by the iTunes and are available on the AppStore!

Have you ever wondered how much tool life can deteriorate when using coolant with High-Speed Machining (HSM)?

Or maybe you never really saw the boost in tool life when using HSM techniques because you had to use coolant?

Well, here is a test result I just got from running the same tool at the same Speed and Feed with and without coolant.

We all know what the CNC Milling Machine spindle is used for - to hold the tool. But it is old and boring. Everybody does that.

Here are the 6 interesting and maybe less common ways to utilize machine spindle, increase productivity and solve some problems you never thought you had.

I saw this little gadget at a local IMTS show and it was quite cool. It is installed into a tool holder like a regular cutting tool would be and at the end of the program you can call the it up and run a little table-cleaning program to make your work a lot cleaner!

© 2009-2022 Eldar Gerfanov. All Rights Reserved.

© 2009 Eldar Gerfanov. Materials on this site are presented as is and are mostly for educational use.

You may freely reproduce information presented herein without any consent from me, provided you include link to this site.

In case when i am not the copyright holder, you may want to contact proper owner of material. Anyway, they are freely available on the Internet.

If you hold the copyright right for any of the materials on this site and want them removed, please contact me here