Avid CNC Benchtop Pro vs Mild Steel - can we cut steel on a desktop gantry router?

Just found a very good video of testing a table-top gantry router cutting mild steel.

YouTuber named "Breaking Taps" used speeds and feeds generated by HSMAdvisor to get a starting point.

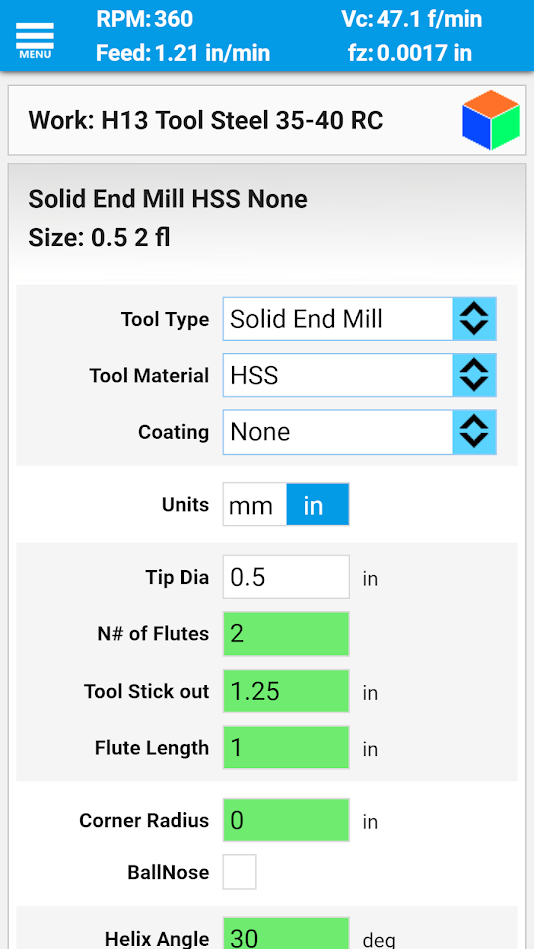

To see where exactly he was in the calculations I decided to reproduce all of cuts in HSMAdvisor.

A couple of assumptions i made:

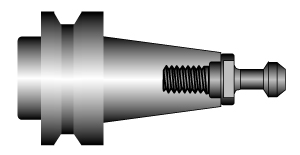

- Tool Type: Solid End Mill. It is not recommended to use the HP/Roughing tool type on such light machines, so i assumed this is the tool BT used.

- Tool Stick-out looked like about 3/4" so I used that number.

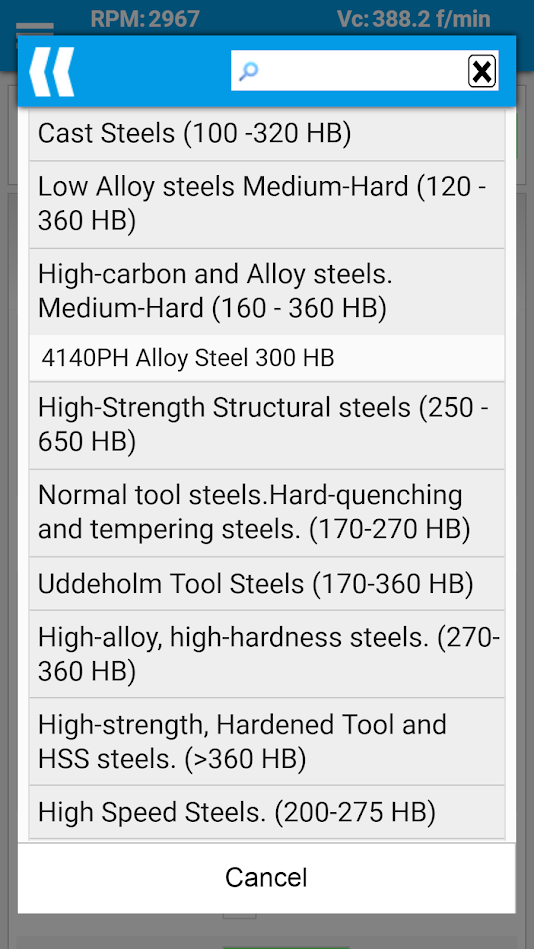

- Material was set to A36 Hot rolled steel.

Test 1) Minute 4:52

Good, slow and very safe starting point.

Test 2) Minute 6:20

Twice as aggressive as before, but we can still push it further.

Test 3) Minute 7:10

Here we can see the lack of machine rigidity starting to show. But at 65% feed rate it is still alive.

Test 4) Minute 8:30

This last test did not go well at all.

The machine has finally hit its limit and the endmill broke at all S&F overrides at about 100%

Was this fault of the software? Not really!

If that were a heavier machine, the last cut would not even be considered that difficult.

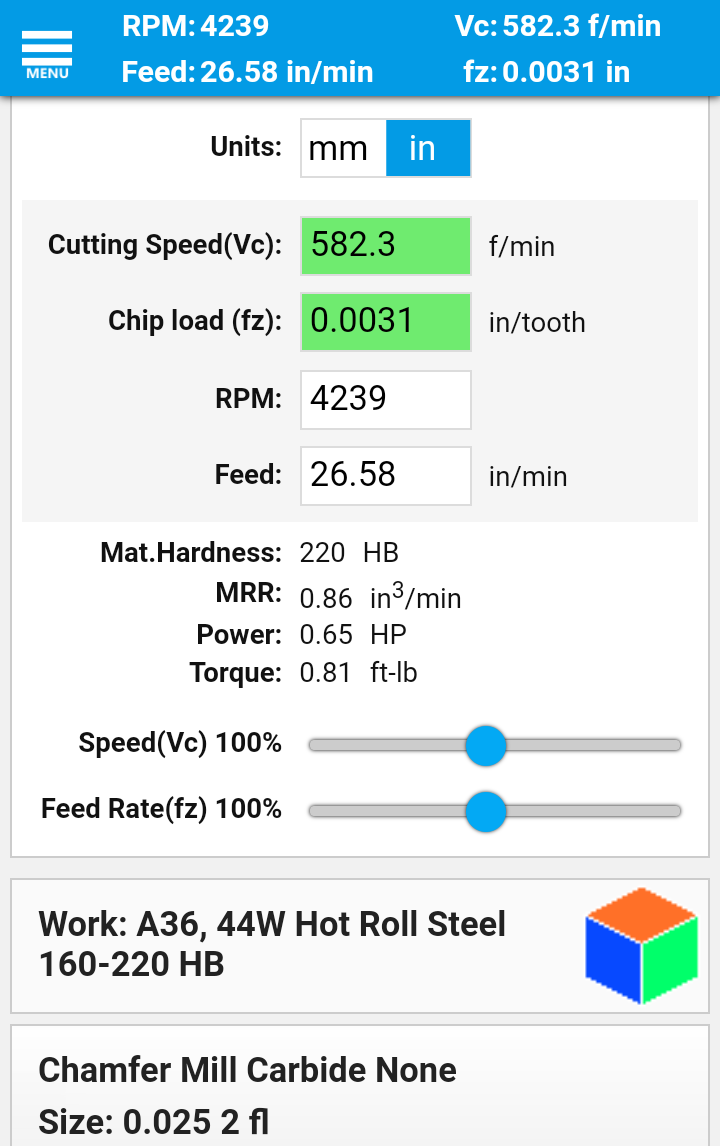

Here is a full slotting cut on a Matsuura VMC:

And here is the calculation that was done using HP/Roughing End Mill tool type:

If i were using the "Solid End Mill" tool definition, i would have to dial the feed override to 176% to match the 45ipm feed rate!

So what can users of light machines do in order to not break taps end mills?

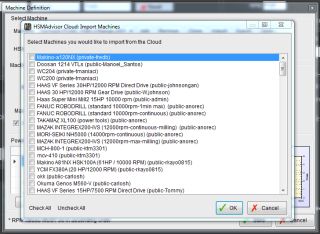

First of all make sure the spindle torque curve is built and enabled in your machine profile settings.

The easiest solution is to de-rate the spindle. There is "Warning at" level in machine profile settings. Set that to 50% for starters and it should save you from exceeding the machine's capabilities.

Overall this was a great test of this little machine's capabilities and of the great help that software like HSMAdviasor can lend in discovering them.

Please head over to Breaking Taps YouTube account and subscribe.