Expanding Mandrel with Outside Support

February 27, 2016, 1:21 pmArticle Summary

Eldar Gerfanov (Admin)

February 27, 2016, 1:21 pm

Eldar Gerfanov (Admin)

February 27, 2016, 2:42 pm

6072

6

Public

Author Summary

Thu January 22, 2026, 5:11 pm

Thu January 22, 2026, 5:11 pm

Being a CNC Machinist/Programmer is sometimes more than simply creating a program and machining the actual part, often times it is about creating efficient and accurate fixturing.

In this little project:

I had to machine rectangular cut-outs and drill holes through an already-turned steel ring. Then I had to part each ring to 4 equal pieces.

There were about 100 such rings that worked out to 400 pieces in total.

After drilling holes on an indexer I had to machine a fixture to hold my part through 2 remaining set-ups.

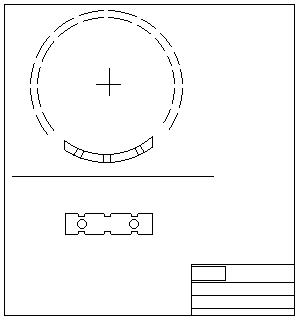

First half of the fixture consists of the expanding mandrel:

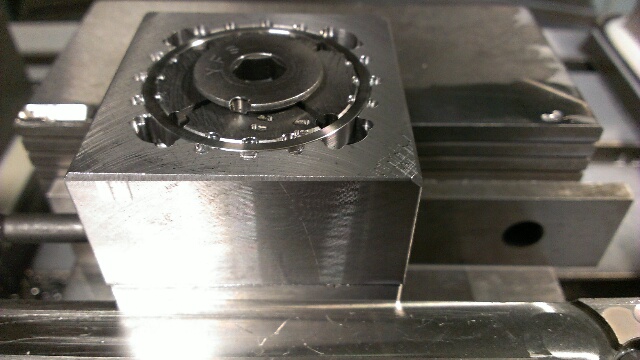

The work-piece would be mounted on it like so. A hole on the side is used to properly position it:

The mounted part already has cut-outs machined in the first op on the same fixture.

After slightly tightening the screw, the second half of the fixture is installed. It keeps the 4 machined pieces in place after they are parted from each other:

Then the screw is tightened even more until I can no longer turn the top half of the fixture by hand.

Both the lower and the upper halves are machined to slide-fit to the work-piece, so that when the mandrel expands it clamps the work-piece against the upper half.

By the marks on the fixture you can see where machining was taking place.

And yes, I accidentally machined my fixture by crashing a small end mill into it - MasterCAM did some weird stuff with rotating my toolpaths and messed up the g-code.

Unfortunately I forgot to snap a picture of the finished part.

But I think it is clear from the sketch how it should have looked.

This is one of those cases when coming up with a fixture takes more time and effort than programming and machining the part itself.

And its fun!

Cheers!