Workholding: Soft jaws in Vise

August 24, 2015, 6:01 pmArticle Summary

Eldar Gerfanov (Admin)

August 24, 2015, 6:01 pm

Eldar Gerfanov (Admin)

March 18, 2017, 7:40 pm

9280

81

Public

Author Summary

Tue January 27, 2026, 8:16 am

Tue January 27, 2026, 8:16 am

One of the most versatile ways of clamping irregular -shaped parts is with use of soft jaws.

In this one I had to machine a triangular-shaped part from two sides.

It is going to be some sort of a part holding jaw for a robot.

So step one: Machine one side of the part in vise. hold on to 1/8" of stock. So make sure to cut your part on a bandsaw oversize.

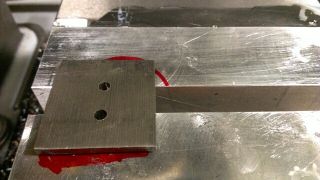

Step Two: Bolt soft jaws to your vise and machine a pocket using outside contour of your part.

Be sure to relieve corners.

Step three: Clamp your part in the soft jaws and machine the second side of your part.

One important thing to consider is: this method is not very accurate. depending on the size and a shape of your part you may be able to hold it within 0.001" though.

See attached photos of the steps below.