Programming Efficient Peck Drilling Cycle

June 2, 2012, 8:18 amArticle Summary

Eldar Gerfanov (Admin)

June 2, 2012, 8:18 am

Eldar Gerfanov (Admin)

February 13, 2025, 1:02 am

63492

Public

Author Summary

Thu January 8, 2026, 9:02 pm

Thu January 8, 2026, 9:02 pm

Optimizing Peck Drilling for Deep Holes

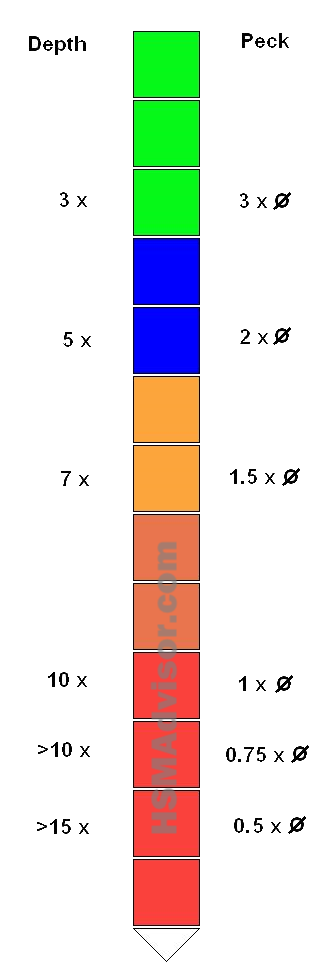

Peck drilling is often necessary when machining deep holes. However, with the correct feed and speed settings, pecking is unnecessary for depths up to:

- 3× diameter for standard drills

- 5× diameter for high-performance parabolic drills

For deeper holes:

- Up to 10× diameter → Up to 5 pecks for regular drills, and up to 3 pecks for parabolic drills

- Beyond 10× diameter → Constant pecking is required:

- 0.5–1× diameter per peck for regular drills

- 1.5–2× diameter per peck for parabolic drills

Since programming requires specifying a peck amount, here are the recommended values:

Peck Drilling Guidelines

Regular Jobber Drills

- Up to 3× dia: No peck

- 3×–10× dia: 1× dia peck

- Over 10× dia: 0.75× dia peck

- Over 15× dia: 0.5× dia peck

High-Helix HP Drills

- Up to 5× dia: No peck

- 5×–10× dia: 2× dia peck

- Over 10× dia: 1.5× dia peck

Our HSMAdvisor Speed and Feed Calculator not only suggests speeds and feeds but also recommends proper peck depths for various drill types and hole depths. In fact, it was the first machinist calculator to offer this feature—later adopted by competitors.

And here is a pretty image showing Peck VS Hole Depth for regular twist drill:

Peck Drilling Strategy

The peck amount should vary based on drill style and hole depth. Additionally, peck size should decrease progressively as the hole gets deeper. Ideally, start with larger pecks and gradually reduce the size as drilling progresses.

Let's explore how to apply this in toolpath programming.

Standard Peck Drilling Format

- X Y: Hole location

- L: Number of holes (if using incremental mode G91)

- R: R-plane position

- Q: Peck depth

- P: Dwell time at the last peck (seconds)

- F: Feed rate

- Z: Target depth

(T15 7/32 HiHelix DRL DEEP a 3.5" Hole)

(Tool # 15 Drill: .21875 )

T15 M6

S6400 M3

G90 G0 X-0.5 Y-1.0

M8

G43 Z0.5 H15

G83 X-0.5 Y-1.0 Z-3.5 Q0.375 R0.1 F48.

G80 G0 Z0.5

...

Variable Peck Drilling

Many CNC machines support variable pecking cycles, allowing deeper pecks at the start and shallower pecks as drilling progresses. This improves tool life and significantly reduces cycle time.

- X Y: Hole location

- L: Number of holes (if using G91)

- R: R-plane position

- I: Initial peck depth

- J: Peck reduction per pass

- K: Minimum peck depth

- P: Dwell time at the last peck (seconds)

- F: Feed rate

- Z: Target depth

(T15 7/32 DRL DEEP a 3.5" Hole)

(Tool # 15 Drill: .21875 )

T15 M6

S6400 M3

G90 G0 X-0.5 Y-1.0

M8

G43 Z0.5 H15

G83 X-0.5 Y-1.0 Z-3.5 I1.125 J0.1875 K0.375 R0.1 F48.

G80 G0 Z0.5

...

FANUC Macro for Progressive Pecking

For FANUC controls that do not support variable pecking, here’s a macro subroutine contributed by a user named Norman:

O0001

(Fast Pecking)

G0 G28 G91 Z0. W0.

T1 M06

S1000 M03

G90

G56

G00 G43 Z1.

X0. Y0.

M98 P1111

G00 X2. Y0.

M98 P1111

G00 X2. Y2.

M98 P1111

G00 X0. Y2.

M98 P1111

M30

O1111

#1=0.0 (Top of hole)

#2=-1.0 (First peck depth, negative)

#3=0.5 (Peck reduction)

#4=-0.1 (Minimum peck, negative)

#5=-2.5 (Total depth)

#6=10.0 (Feed rate)

#7=0.1 (Top hole clearance)

#8=[#1+#7]

#9=#8

#11=#2

#12=[#1+#2]

WHILE [#10 EQ 0] DO1

G00 Z#9

G01 Z#12 F#6

G00 Z#8

#9=[#12+0.1]

IF [#12 EQ #5] THEN #10=1

#11=[#3*#11]

IF [#11 GT #4] THEN #11=#4

#12=[#12+#11]

IF [#12 LT #5] THEN #12=#5

END1

M99

%

Final Thoughts

Implementing variable pecking can drastically improve efficiency and tool life. In my own experience, when drilling thousands of deep holes in large molds, this method reduced cycle time by 50–70% compared to regular peck drilling.

If your CNC supports variable pecking, be sure to use it—it optimizes drilling depth and efficiency, ensuring a smoother and faster operation.

Tom

Excellent explanation of the G83 function!

Miguel

There is some reference for the depth in the different materials?

Eldar Gerfanov (Admin)

Updated by: Eldar Gerfanov (Admin)January 8, 2026, 9:02 pm

Nguyen Van Du

Thanks your information! Useful experience.